Did you know MIPAQ supplies a wide range of ORIGINAL MEC spare parts for all MEC sealers ?

If you are using MEC heatsealers for your packaging and sealing applications, you know how reliable and efficient they are. But like any other machine, they need regular maintenance and replacement of worn-out parts to keep them in optimal condition. Impulse type heat sealers in particular need continued maintenance on the Teflon tape, sealing element wire and silicon rubber press pad to ensure that you get an excellent seal. In order to ensure correct performance it’s important to use ORIGINAL spare parts only for your MEC sealers.

Always use original MEC spare parts for your MEC sealers

Other brands of heatsealers may appear to have similar looking parts, but they are almost always made from inferior material, or are thinner, shorter, or physically different making them not compatible at all with MEC machines. Even if it does manage to fit, the part will almost always be of incorrect specification and cause further damage to your MEC machine, such as causing the element to snap, Teflon tape to burn or a transformer or control timer PCB to blow!

We offer an extensive range of MEC spare parts

MIPAQ has been the agent for MEC brand heat sealers in Southern Africa for over 20 years, during which time, MEC has consistently been regarded as the highest quality sealing machine brand in the SA market. With this reputation comes an expectation of high quality, performance and longevity. Unlike cheap Chinese machines which are considered consumable or ‘throw-away’, we regard our MEC sealers as serious industrial grade equipment that should last for years. As such we stock and supply a wide variety of all common (and even uncommon) parts for more than 40 models of MEC sealing machines, including:

- Element wires ranging from 100mm to 1000mm and available in a variety of thicknesses including 1mm, 2mm, 3mm, 5mm, 10mm, specific to corresponding models.

- Control timers for hand operated, foot operated, impulse, constant heat type and more.

- Teflon tape, both adhesive and non-adhesive in numerous widths, normally sold per 30m roll or per meter. We also offer teflon sheets for foot operated sealers. Teflon tape is very important for insulating the element wire and delivering a perfect seal. Burnt or torn Teflon should be changed routinely.

- Silicon rubber press pads, for all our models. Silicon rubbers have specially profiled shapes to fit into specific models. Some of our silicon rubbers are able to be reversed ( used on the opposite side) doubling their usage and improving longevity. Check for burnt holes or damage to the flat silicon surface, which can impair your seal quality and cause your element to burn and snap prematurely.

- Transformers. MEC transformers are generally larger and more powerful than those found in other brands. The other electrical components such as control timers, element wires, internal wiring etc are designed for the specific wattage. As such, it is very important to always replace an MEC transformer with an original MEC replacement part, and not to try using a cheap alternative.

- Springs. We offer a wide range of internal and external springs for hand operated and foot operated machines.

- Microswitches , also called limit switches are available for all models.

- Element connectors often wear down and need replacing to ensure good contact with the element and therefore optimal performance.

- We offer a wider range of components direct from the manufacturer on all models, especially for foot operated type, continuous band type and semi-auto sealers that have numerous unique components. Enquire with us if you are not sure what parts you need.

By buying spare parts from MIPAQ, you can ensure that you are getting original and high-quality parts direct from the factory, that are 100% compatible with your MEC machines. You can also benefit from their expert advice and technical support, as well as their fast and reliable delivery service. We can also repair and service your machine for your, or alternatively recommend reliable third party technicians near you.

Avoiding costly repairs with Routine Maintenance

Using original MEC components from MIPAQ can help you extend the lifespan of your MEC sealing machines and prevent costly breakdowns and downtime. By doing so you can maintain the quality and consistency of your packaging, as well as the safety and hygiene of your products. It is not advised to use non-MEC components when repairing or maintaining MEC sealing machines, as this may cause irreparable damage in the long run.

We recommends that you perform continuous scheduled maintenance on your MEC sealers, following the manufacturer’s instructions and guidelines described in the manual. If you do not have a manual or parts list please feel free to contact us and we will gladly provide you with a pdf copy via email. Familiarize yourself with the common consumable/ wear ‘n tear parts so that you can monitor and detect any signs of wear and tear, and be able to replace the parts before they cause any damage or malfunction.

How to Order Spares from MIPAQ

- Provide the model of the Machine. this is often found on a label or sticker on the side of the machine. If in doubt view our range on this website to identify your sealer or send us a picture.

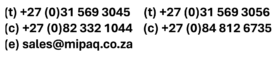

- Using the parts list supplied with your MEC machine or downloaded from this website identify the part and quantity you require. Email you enquiry to sales@mipaq.co.za or call us on 031 569 3045.

- if you are in doubt as to what the part is , you can always email us a picture of the damaged component along with the model number or picture of the machine and we will assist in identifying the correct piece required.

Don’t wait until it’s too late. Contact us today and order the spare parts you need for your MEC heat sealers. You can submit an enquiry by clicking here , email us at sales@mipaq.co.za , or call us on 031 569 3056. We will be happy to assist you with your packaging needs.